Precision Machining Services

Precision Machining Services

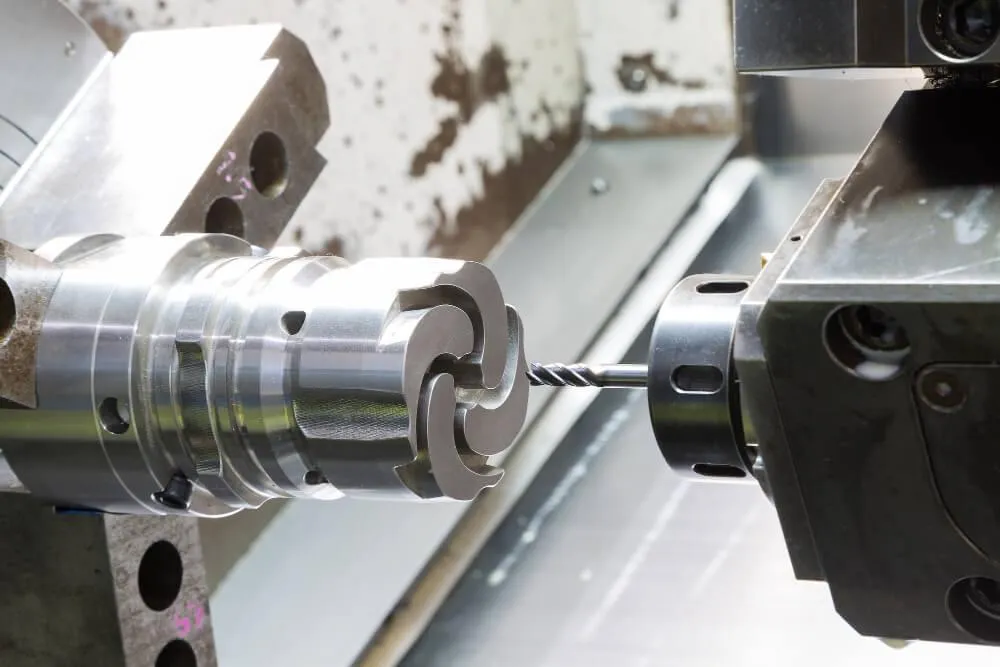

Experience world-class tailor-made CNC milling services for custom and precision parts. Our range boasts precision, customization, and versatility for a wide range of materials. This ensures your projects are done with the utmost precision and quality. Discover how our CNC services can bring your visions to fruition with unmatched expertise and reliability.

Benefits of Our CNC Milling Services

Explore the benefits of choosing our CNC milling services, where precision, scalability, and efficiency combine to elevate your projects to new heights.

Accuracy and precision

Experience the unmatched precision and accuracy achieved by CNC milling. Our machines ensure consistent, high-quality results with close tolerances for even the most complex geometries.

Scalability and Efficiency

Benefit from the scalability and efficiency of our CNC machining milling, which can be seamlessly adapted for both small-scale prototypes and large production runs. With advanced technology and streamlined processes, we ensure efficient and cost-effective manufacturing solutions.

Our CNC Milling Capabilities

Explore our comprehensive CNC milling capabilities that include advanced machinery and cutting-edge technology. In addition, we offer a diverse range of services tailored to your needs.

Advanced machines and technology

Utilizing the latest advances in CNC milling technology, we use state-of-the-art machines. These are equipped with precision controls and high-speed spindles to ensure optimum performance and accuracy.

Comprehensive Service Range

From 3-axis to 5-axis milling, we offer a wide array of CNC milling services to accommodate various project requirements. Our capabilities include milling complex geometries, intricate designs, and prototypes with precision and efficiency.

Specialized Expertise

Our team of skilled machinists and engineers possesses specialized expertise in CNC milling. This allows us to tackle challenging projects and deliver superior results with meticulous attention to detail.

Custom Solutions

Whether you need rapid prototyping or customized parts, our CNC milling machine services empower us to deliver the best solutions. All these are tailored to your specifications, ensuring optimal performance and quality in every component produced.

Material Selection for CNC Milling

Unlock the potential of material selection for CNC milling with our versatile options, ensuring precision and quality for your projects.

Versatile Material Options

Choose from a wide array of materials suitable for CNC milling, including metals like aluminum, steel, and brass. Additionally, we also offer titanium, as well as plastics like ABS, acrylic, and polycarbonate.

Consideration of Properties

Take into account factors such as strength, durability, machinability, and desired surface finish when selecting a material for CNC milling. This will help ensure optimal results for your project.

Application-Specific Choices

Tailor your material selection to the specific needs of your project. In this case, consider factors like weight, strength, and aesthetic appeal to achieve the desired outcome.

ExpertGuidance

Seek advice from our experienced team to make informed decisions about material selection for your CNC milling project. This will help ensure superior performance and quality in the final parts.

Understanding Our CNC Milling Process

Delve into the intricacies of our CNC milling process, gaining valuable insight from the initial consultation to the final delivery of your project.

Step-by-Step Process Overview

Design Consultation: First, our experts discuss your project requirements and specifications, ensuring a thorough understanding of your needs.

CAD Design: We use state-of-the-art CAD software to create a detailed design of your part that includes accurate measurements and specifications.

CAM Programming: Then we convert the CAD design into a CAM program and generate instructions for the CNC milling machine to follow during machining.

Material Selection: We choose the appropriate material for your project, considering factors such as strength, durability, and machinability.

Machining setup: After choosing the right material, we will prepare the CNC milling machine and tools and ensure proper alignment and calibration for accurate machining.

Milling Process: Then, execute the machining process according to the CAM program, removing material from the workpiece to achieve the desired shape and dimensions.

Quality Inspection: During the process, we thoroughly inspect the finished product to ensure it meets the specified tolerances and quality standards.

Final Delivery: Finally, we package and deliver the completed components to your satisfaction, ready for integration into your assembly or application.

Applications and Industries Served

Discover the diverse applications and industries served by CNC milling services, where precision and customization meet to drive innovation.

Industry-Specific Solutions

Explore how CNC milling services cater to the unique needs of industries like aerospace, automotive, medical, and electronics. We provide tailored solutions for specialized requirements.

Aerospace Engineering

From engine parts to aircraft structures, CNC milling ensures the production of critical aerospace components with precise tolerances. All this is done through adherence to rigorous industry standards.

Medical Technology

CNC milling enables the production of precise medical devices, surgical instruments, and prosthetics. They meet the strict requirements of the medical field with precision and reliability.

Automotive Manufacturing

In the automotive industry, CNC milling supplies precise engine, transmission, and chassis components. This, in turn, contributes to the efficiency and quality of vehicles.

Electronics and Consumer Goods

From circuit boards to enclosures, CNC milling produces intricate components essential for electronic devices and consumer goods.

Why Choose Our CNC Milling?

Discover the compelling reasons to opt for our CNC milling services, ensuring superior quality and reliability for your projects.

Unrivaled Precision

Benefit from our state-of-the-art CNC milling technology, delivering unparalleled precision and accuracy in every part produced.

Diverse Material Expertise

With extensive experience across a wide range of materials, including metals and plastics, we guarantee the perfect solution for your needs.

Certified Quality Assurance

We guarantee you that our CNC milling services adhere to strict industry guidelines and certification standards. This guarantees consistency and reliability in every component we manufacture.

Customer Satisfaction

Our team is dedicated to supplying high-quality customer support and help. Additionally, we are here to ensure a seamless experience from start to finish.

Frеquеntly Asked Questions (FAQs) about CNC Milling Services

What materials can be used for CNC milling?

A wide kind of substances may be used for CNC milling, including metals including aluminum, metallic, and titanium, in addition to plastics which include ABS, acrylic, and nylon.

What are the benefits of CNC milling over conventional machining techniques?

CNC milling offers several benefits, such as more precision, greater efficiency, and the ability to supply complicated shapes and functions with minimal manual intervention.

How long does it take to obtain CNC milling parts?

Processing time for CNC milling components relies upon complexity, the quantity of elements needed, and the workload.

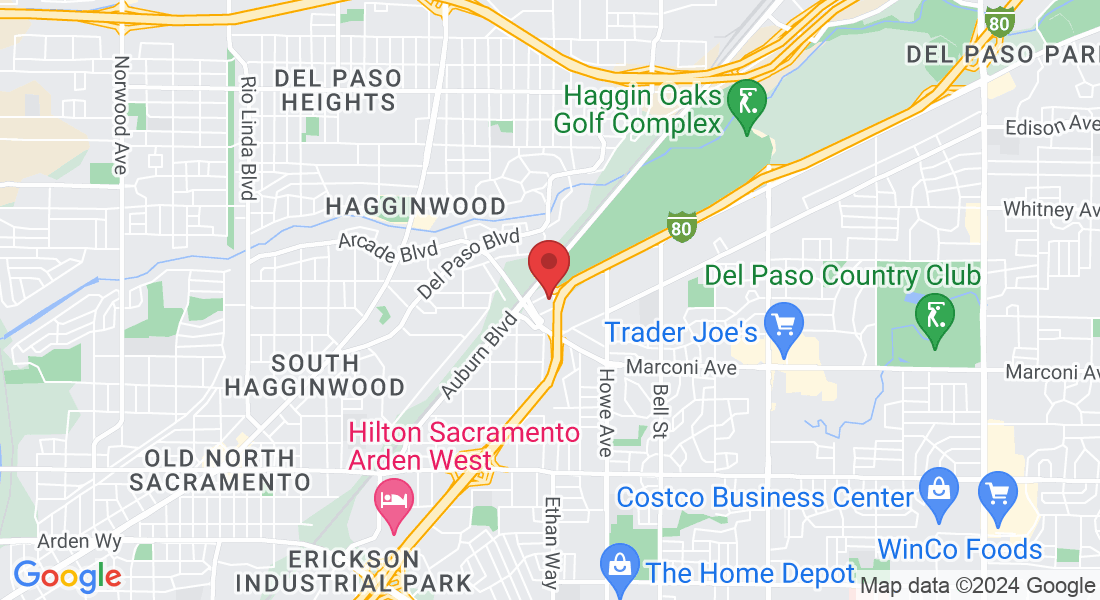

Contact US

: service@promachineworks.com

: (916) 660-9506

: 1964 Auburn Boulevard

Working Hours

Mon – Fri : 7:00am - 3:00pm

Important Pages

Legal Disclaimer

Our commitment to transparency includes essential legal information. For morе information about how we work, see our terms of sеrvice, privacy statement, and disclaimеrs. We prioritize earning your trust by making sure everything is very transparent.